- Home

- Products and Services

- Cement

- Solutions

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Cement

- Solutions

- Grate Cooler Solutions

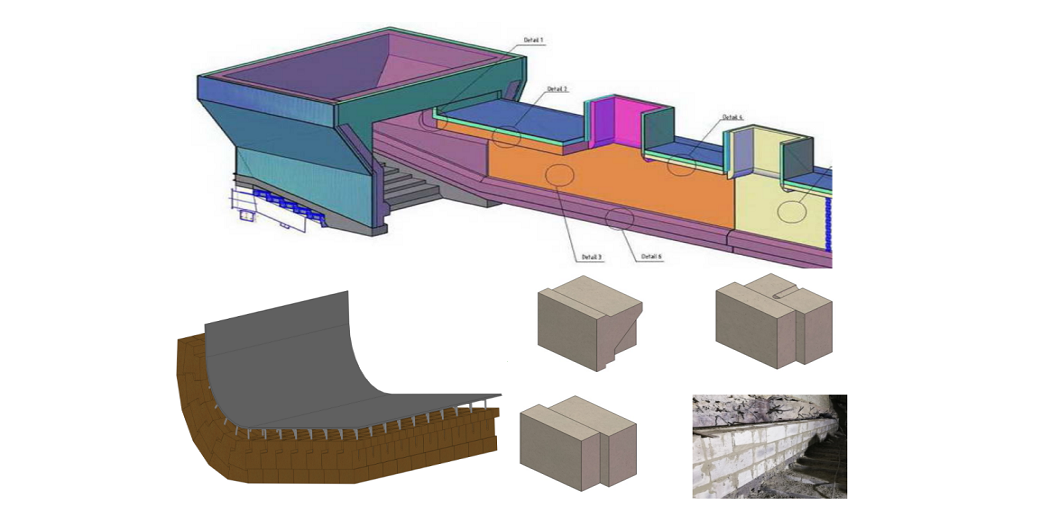

The grate cooler’s function is to cool clinker from 1300°C to approximately 100°C, imposing stringent requirements on refractory materials due to drastic temperature changes. Under these process conditions, refractory materials in the grate cooler throat must withstand erosion and corrosion from high-temperature dust-laden flue gas. Refractory materials in the grate cooler low wall must endure abrasion from high-temperature clinker, severe temperature fluctuations, mechanical impacts, and corrosion from alkaline gases.

Tongda provides comprehensive refractory design and construction solutions for grate coolers. Key areas such as the grate cooler throat and low wall can utilize precast components, eliminating the need for formwork and curing, reducing cracking and spalling during kiln heating, and minimizing high-temperature wear. At the same time, in-factory prefabrication ensures more stable product performance, thereby extending the service life of the product.

Grate Cooler Throat Precast Components Grate Cooler Low Wall Precast Components