Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Environmental Protection

- Solutions

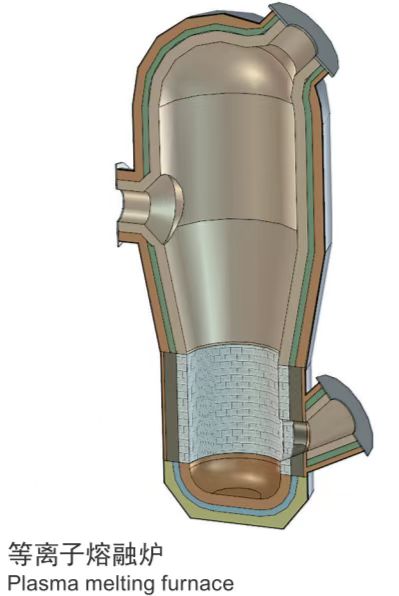

- Plasma furnace

After waste undergoes thermal treatment in an incinerator, a certain amount of residual material remains, along with fly ash collected from dust collectors. These incineration residues often contain significant amounts of hazardous heavy metals, while the fly ash is rich in dioxins and other harmful substances. Both the incineration residues and fly ash must undergo further detoxification treatment before they can be safely landfilled. Using a plasma melting furnace to carry out final melting treatment of the fly ash and incineration residues is the most effective method for achieving waste detoxification and stabilization. This technology offers distinct advantages: organic substances in the incineration ash are completely decomposed and combusted; inorganic substances are vitrified; and most heavy metals are stably solidified within the vitrified slag. The resulting vitrified material can be reused as raw material for ceramics, roadbed construction, and cement production.