- Home

- Products and Services

- Energy

- Product

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Energy

- Product

- Thermal power generation

- Wear-Resistant Refractory...

Wear-Resistant Refractory Castable

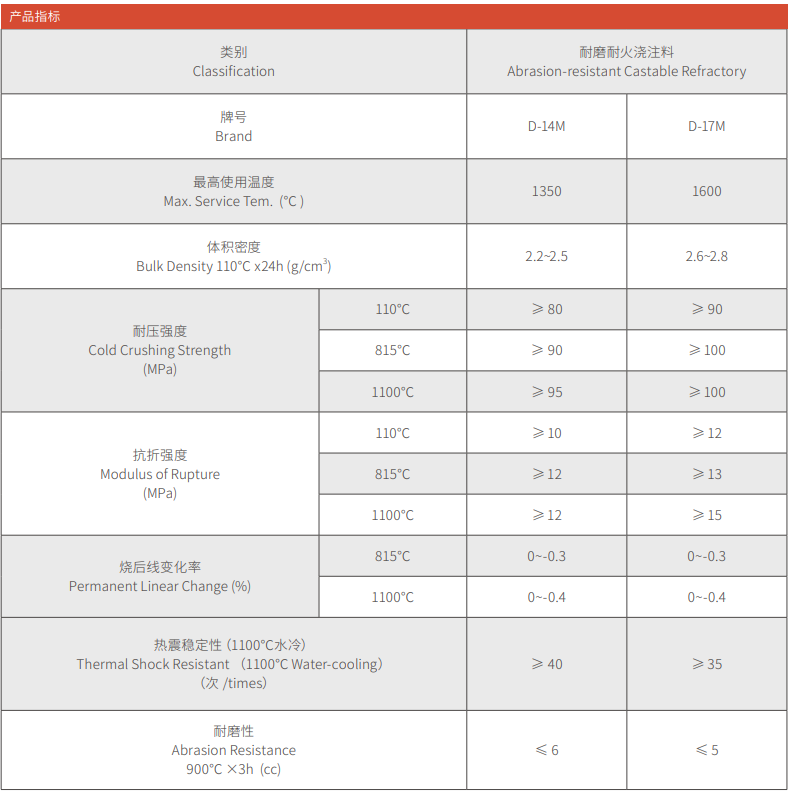

【Product brand】D-14M/D-17M

【Recommended use】Dense phase zone of the furnace and its outlet flue, cyclone separator and its inlet/outlet flues, return feeder, external bed, and slag discharge system

Product Introduction

The high-strength wear-resistant refractory castable D-17M uses high-hardness corundum-mullite as the aggregate, incorporating composite aggregates, ultra-fine powder, and low-cement bonding technology. It is characterized by exceptional wear resistance and high thermal shock stability, with excellent workability that enables self-flow casting.

Compared to traditional wear-resistant refractory castables, the flint clay-based wear-resistant refractory castable D-14M has a lower bulk density. Both products exhibit good wear resistance and thermal shock stability, with an abrasion resistance value of 6 cc or less.

Products Quality