- Home

- Products and Services

- Cement

- Solutions

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Cement

- Solutions

- Kiln Outlet and Burner Pipe Solutions

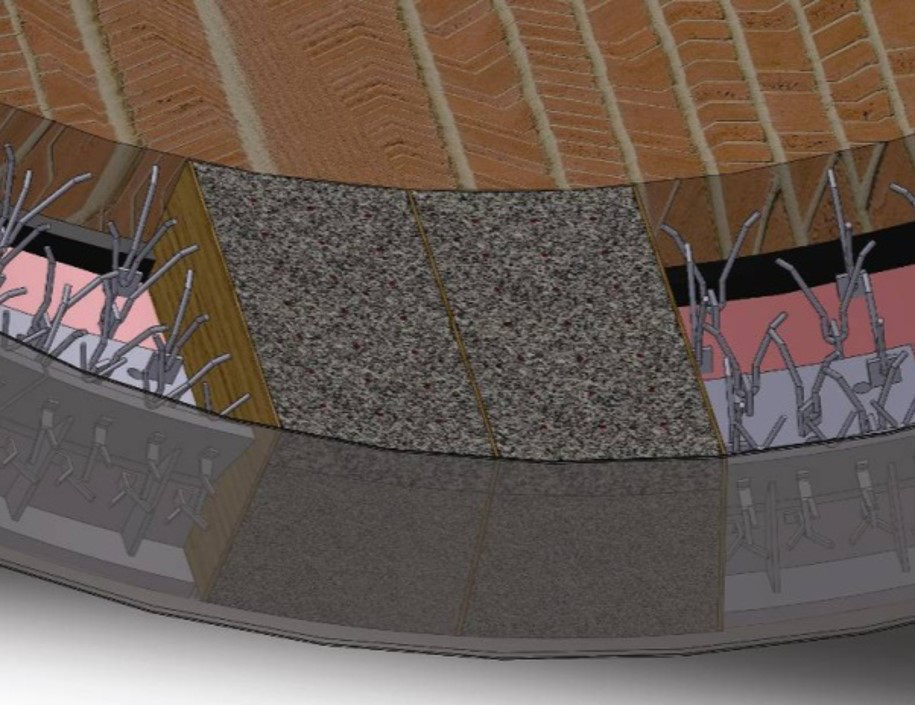

The kiln outlet and burner pipe are the most critical components of the cement kiln firing system and represent the weakest links in the application of refractory materials. These areas must withstand severe temperature fluctuations, abrasion from high-temperature clinker, and mechanical stress from kiln rotation. Therefore, materials used in these areas should exhibit high wear resistance, alkali resistance, thermal shock resistance, and excellent thermal stability.

1. Kiln Outlet Solution

Tongda provides comprehensive diagnostic consulting for kiln outlet refractories and customized, complete refractory design solutions. These include analyses of the cement kiln’s operating environment, production processes, installation techniques, and causes of refractory damage.

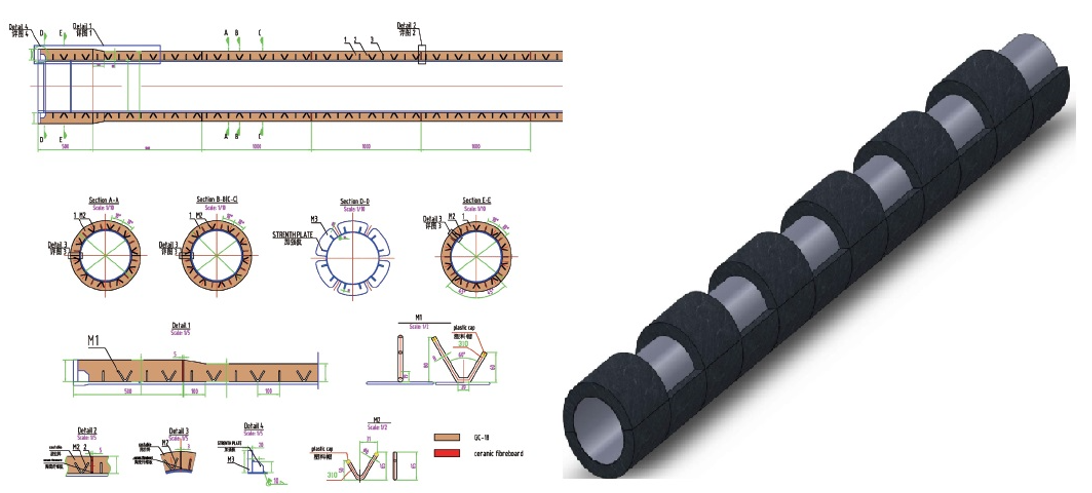

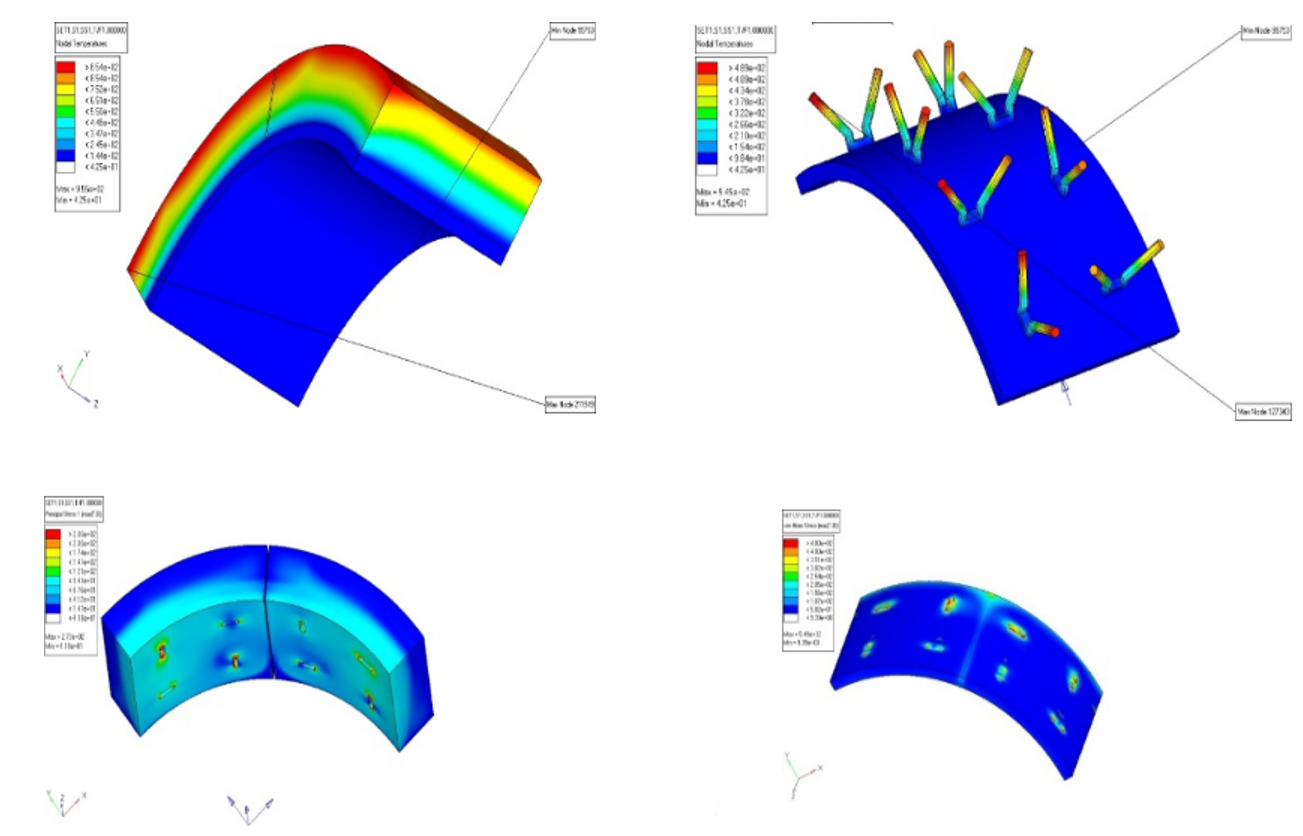

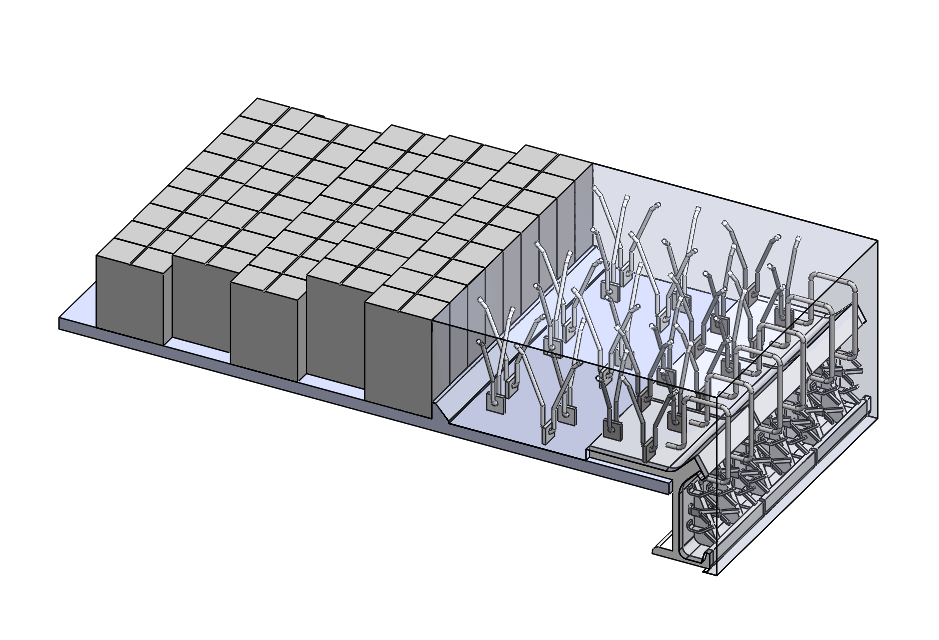

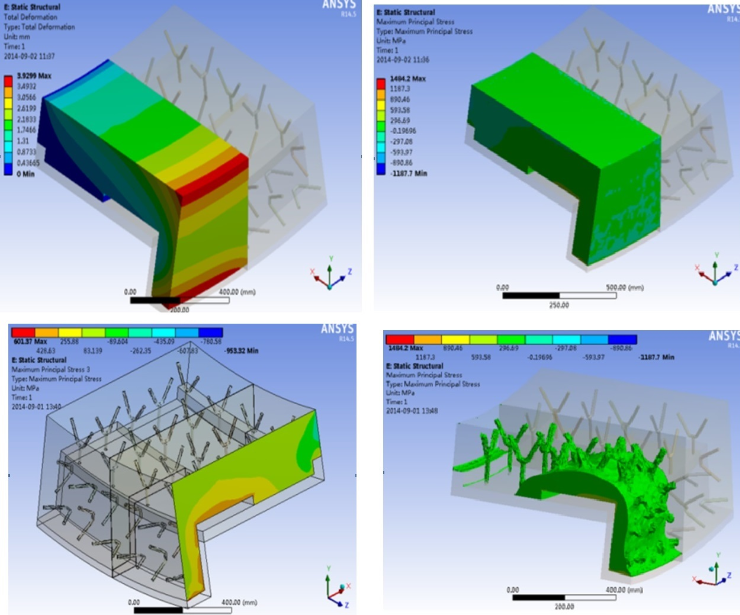

2. Burner Pipe Solution

Tongda offers comprehensive diagnostic consulting for burner pipe refractories and tailored refractory design solutions. These encompass numerical simulations of the burner pipe’s operating environment, installation techniques, temperature fields, and stress fields, as well as analyses of damage mechanisms. Detailed installation drawings, product designs, and construction plans are also provided.