- Home

- Products and Services

- Cement

- Product

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Cement

- Product

- Burner Pipe

- Spalling Resistance Cast...

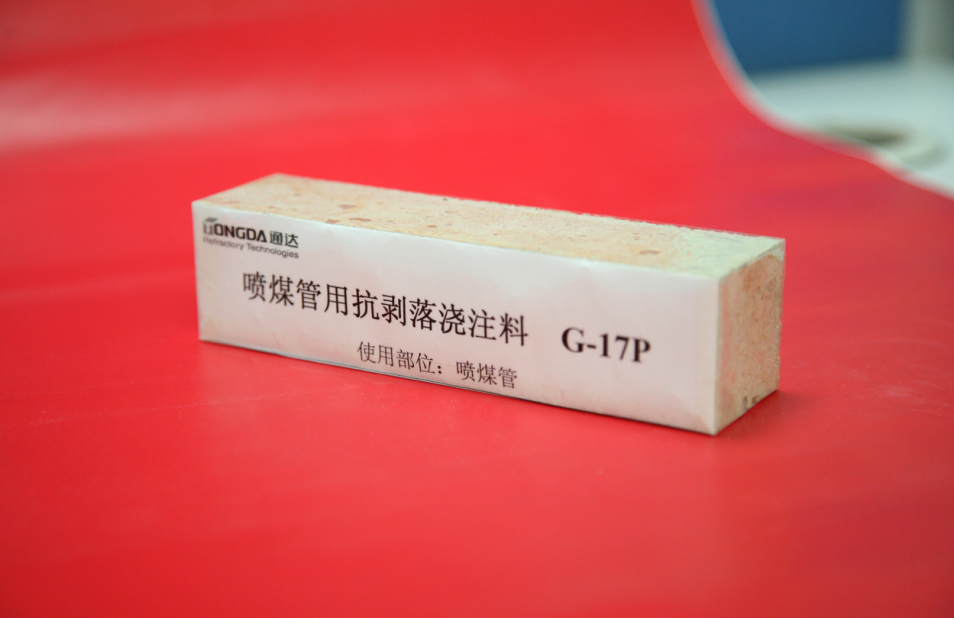

Spalling Resistance Castable for Burner Pipe

【Product brand】G-17P

【Recommended use】Burner Pipe

Product Introduction

Main performance characteristics:

(1) High refractoriness and high hot-state strength.

(2) Excellent thermal shock stability and spalling resistance.

(3) Superior high-temperature resistance to alkali erosion.

(4) The product is cost-effective with a moderate price, making it highly suitable for the working environment of large-scale dry-process cement kiln burners (burner pipes). It is a highly targeted new refractory castable that significantly extends the service life of burner pipes.

Products Quality

|

Product Name |

Spalling Resistance Castable for Burner Pipe

|

|

|

Product Code

|

G-17P |

|

|

Chemical Composition (%)

|

Al2O3+SiC Al₂O₃ + SiC |

≥70 |

|

Bulk Density (g/cm³)

|

110℃×24h 110 °C×24h |

≥2.75 |

|

Modulus of Rupture (MPa)

|

110℃×24h 110 °C×24h |

≥10 |

|

|

1100℃×3h 1100 °C×3h |

≥10 |

|

|

1400℃×3h 1400 °C×3h |

≥8 |

|

Cold Crushing Strength (MPa)

|

110℃×24h 110 °C×24h |

≥80 |

|

|

1100℃×3h 1100 °C×3h |

≥100 |

|

|

1400℃×3h 1400 °C×3h |

≥80 |

|

Permanent Linear Change (%)

|

1100℃×3h 1100 °C×3h |

±0.4 |

|

|

1400℃×3h 1400 °C×3h |

±0.5 |

|

Alkali Resistance

|

1350℃×5h 1350 °C×5h |

Grade II or above |

|

Main Use

|

Burner Pipe

|

|