- Home

- Products and Services

- Cement

- Product

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Cement

- Product

- Other areas

- Precast Refractory Materi...

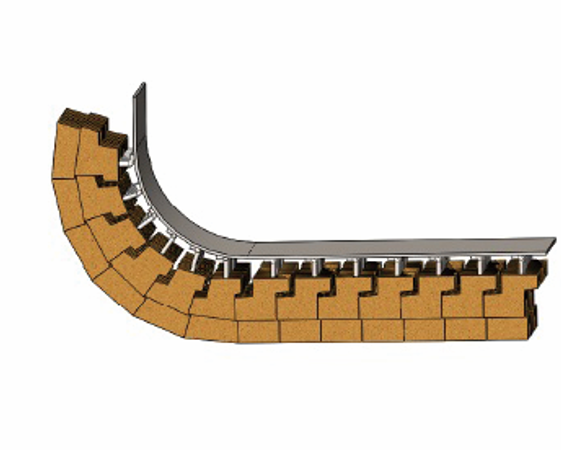

Precast Refractory Materials for Grate Cooler Throat

【Product brand】TD-HB

【Recommended use】Grate Cooler Throat

Product Introduction

(1) The precast components for the grate cooler throat adopt a modular installation approach, requiring no formwork or curing, reducing material cracking and spalling during kiln heating and feeding processes.

(2) Factory-prefabricated components ensure stable quality in terms of strength and other properties, enhancing resistance to fly ash scouring.

Products Quality

|

Product Name |

Precast Refractory Materials for Grate Cooler Throat

|

|

Product Code |

TD-HB |

|

Chemical Composition (%)

|

Al2O3+SiC≥75 |

|

Bulk Density (g/cm³)

|

≥2.60 |

|

Apparent Porosity (%)

|

≤18 |

|

Cold Crushing Strength (MPa)

|

≥100 |

|

Thermal Shock Resistance (1100°C, Water Cooling, Cycles)

|

≥15 |

|

Main Use

|

Grate Cooler Throat

|