- Home

- Products and Services

- Energy

- Product

Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Energy

- Product

- Coke dry quenching

- Other Aspects of CDQ Furn...

Other Aspects of CDQ Furnace

【Product brand】

【Recommended use】

Product Introduction

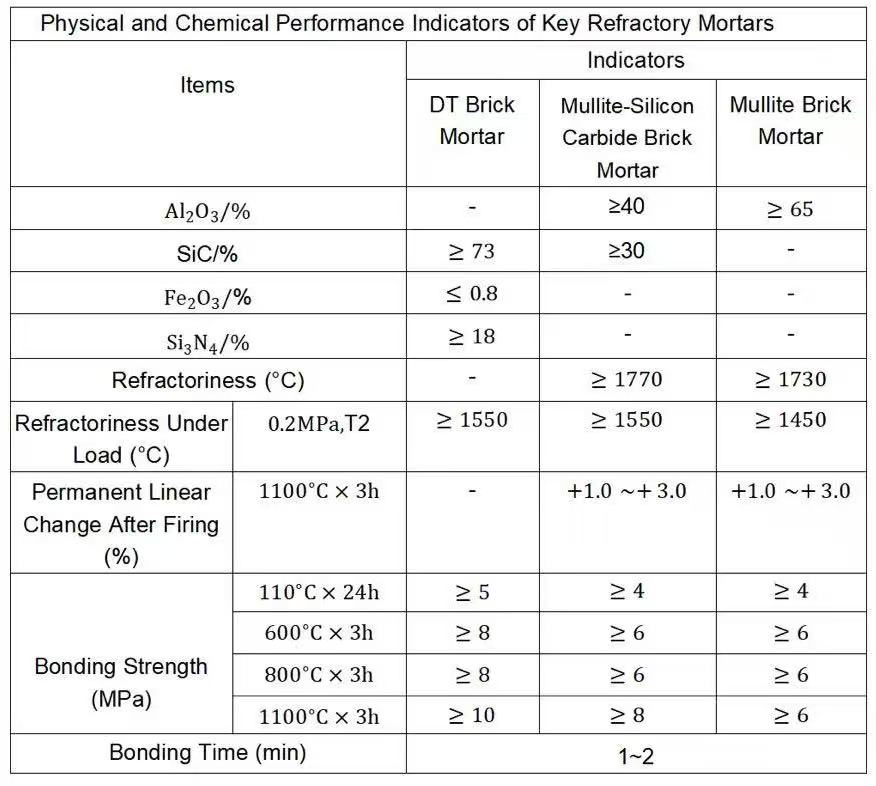

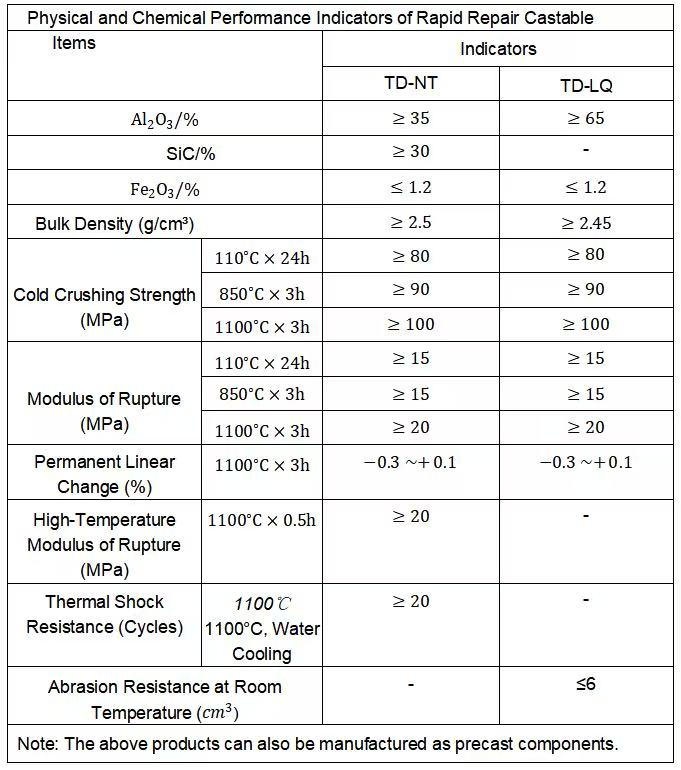

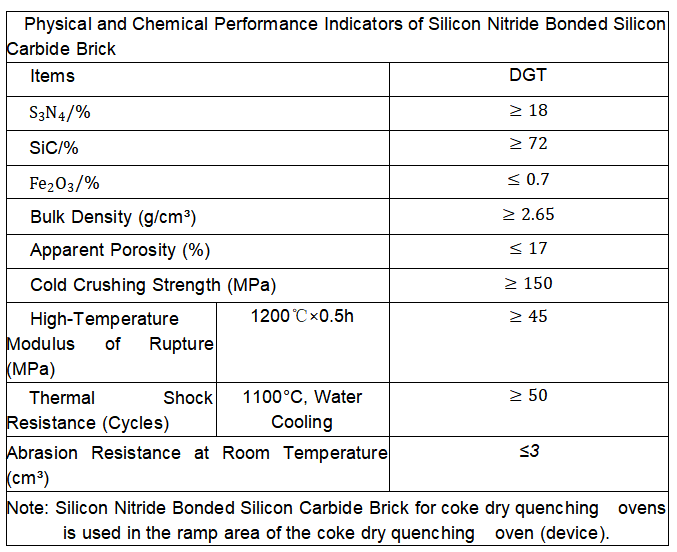

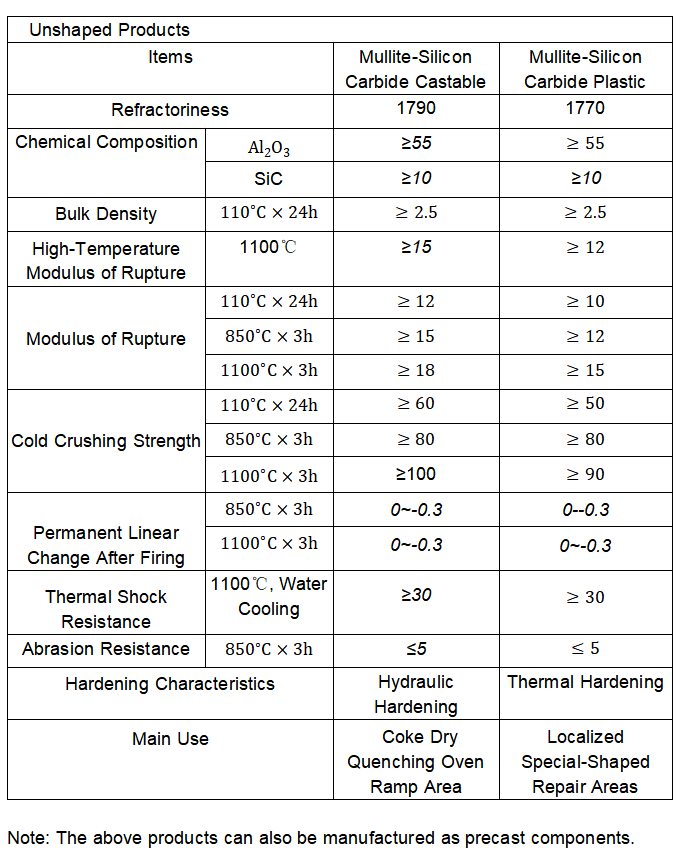

Dry Quenching (CDQ) is a coke quenching technology that serves as an alternative to wet quenching and is one of the energy-saving and environmentally friendly technologies in the steel and coking industries. The CDQ furnace primarily consists of the furnace top, annular air duct, inclined chute, and cooling chamber. It offers the advantages of energy conservation, reduced consumption, and improved coke quality. Seizing environmental opportunities and focusing on energy conservation, the company has organized a scientific and technological team to pioneer the development of high-performance products such as mullite and mullite-silicon carbide series for CDQ applications. It has developed rapid repair technologies for critical components like bullnose and annular air ducts, innovatively designed prefabricated bullnose block assembly solutions, and established a comprehensive integrated technology for refractory materials used in CDQ furnaces.

Tongda Refractory has dedicated over 10 years to the field of CDQ refractories, forming professional capabilities in system design, product development, high-quality manufacturing, and integrated services. With industry-leading core competitiveness and world-class standards, the company is committed to the perfect integration of refractories and thermal equipment, creating value for the long-term stable operation of CDQ furnaces and contributing to energy conservation, emission reduction, and enhanced production efficiency in the coking industry.

Products Quality