Products and Services

- Cement

-

Metallurgy

-

Product

- Blast Furnace Ceramic Cup Series Shaped Products

- Blast Furnace Ceramic Cup Corundum-Silicon Nitride Precast Series Products

- Blast Furnace Ceramic Cup Supporting Slurry Series Products

- Blast Furnace Rapid Repair and Long-Life Series Products

- Refractory Materials for Blast Furnace Taphole

- Belt Roasting Machine Pellet Series Supporting Products

- Grate-Rotary Kiln Pellet Series Supporting Products

- Solutions

-

Product

- Environmental Protection

- Energy

- Aerospace

- Refractory Raw Materials

- Home

- Products and Services

- Refractory Raw Materials

- Product

- Sintered Mullite

- Sintered Mullite

Sintered Mullite

【Product brand】TD-SM60, TD-SM70

【Recommended use】Preferred raw material for shaped and unshaped refractory materials used in critical parts of high-temperature equipment such as steel reheating furnaces, large-scale smelting blast furnaces, hot blast stoves, cement kilns, dry quenching furnaces, and alu

Product Introduction

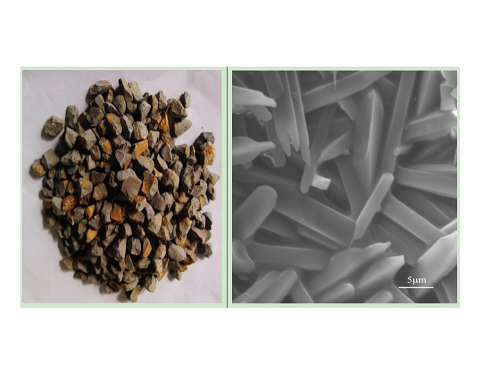

(1) The product is made of high-purity aluminum-silicon raw materials and selected high-grade bauxite, processed through three-step homogenization, wet co-grinding, and ultra-high-temperature calcination.

(2) The product features low impurity content, well-developed mullite crystals, uniform composition and structure, and stable performance.

(3) It can effectively ensure the quality stability of manufactured products, enhance high-temperature mechanical properties, and, as a substitute raw material, significantly improve cost-effectiveness, producing the effects of reduced material use, lightweight design, and extended service life for customers.

(4) It can be used to produce high-quality mullite-based shaped products for steel reheating furnaces, large-scale smelting blast furnaces, hot blast stoves, dry quenching furnaces, and cement kilns, and is the preferred raw material for unshaped refractory materials used in critical parts of high-temperature equipment such as blast furnace repair materials, cement kilns, and aluminum melting furnaces.

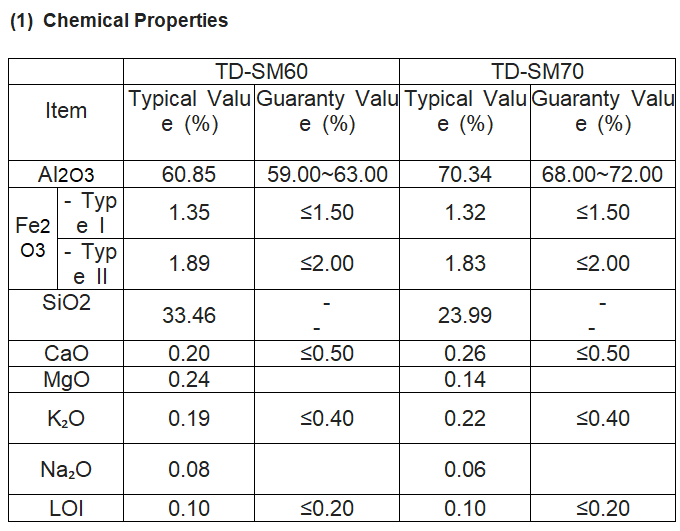

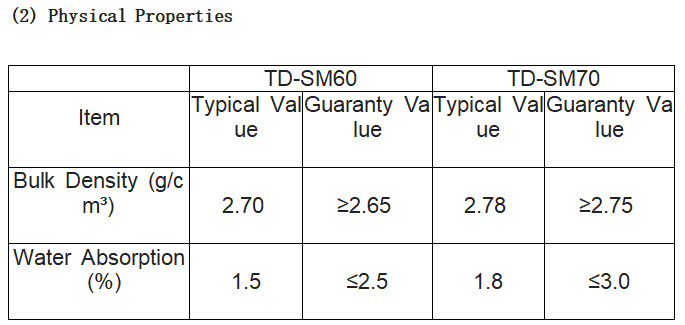

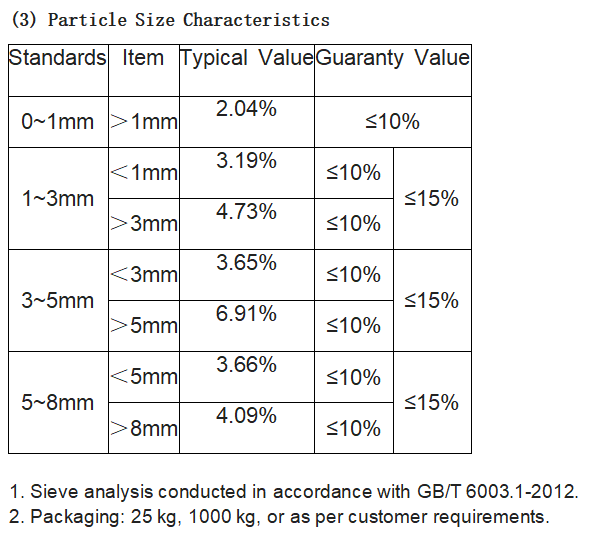

Products Quality